Data Acquisition, Pressure Measurement

Wind Testing of Metal Buildings

Metal buildings are relatively inexpensive, easy to construct and are used extensively for agricultural purposes in the western United States. But metal buildings are light and often present a large flat surface to winds. In areas like West Texas, where local wind conditions can be severe, testing metal structures under field conditions is an important part of specifying safe building codes.

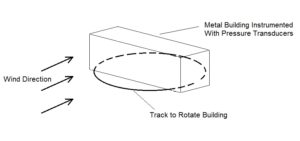

Texas Tech has constructed a field wind testing station in an open field near Lubbock to provide data on wind pressures that are generated under local conditions. A 30 ft X 45 ft X 13 ft prefabricated metal building was anchored to a rigid undercarriage that is mounted on a circular rail track. The entire building can be rotated to create different angles of attack to the prevailing winds. The surrounding area is flat farmland and is representative of the wind conditions in that part of the state. A meteorological tower was constructed nearby to record local wind speed, direction, temperature and barometric pressure. The diagram below shows the concept of the rotatable building.

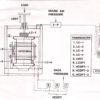

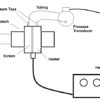

A series of 100 pressure taps were drilled in the various flat surfaces to measure the pressures developed along the outside of the building. Inside, Validyne DP103 pressure transducers were used to measure the pressures. The DP103 is sensitive to low pressures and has a relatively fast response. The DP103 transducers were calibrated to +/-0.18 psi. The recording rate of the transducer pressures is 40 times per second by a PC-based data acquisition system. Up to 96 simultaneous pressure measurements are possible and wind speeds of up to 90 mph can be accommodated.

The pressure data that is collected under various wind conditions and angles of attack are used to calculate the loading force under actual wind conditions so that the anchoring requirements and profiles of prefabricated metal buildings can be specified for maximum safety.

Comments are closed