Aerospace, Automotive, Data Acquisition, Flight Testing, Pressure Measurement

Vehicle Hydraulic Brake System Testing

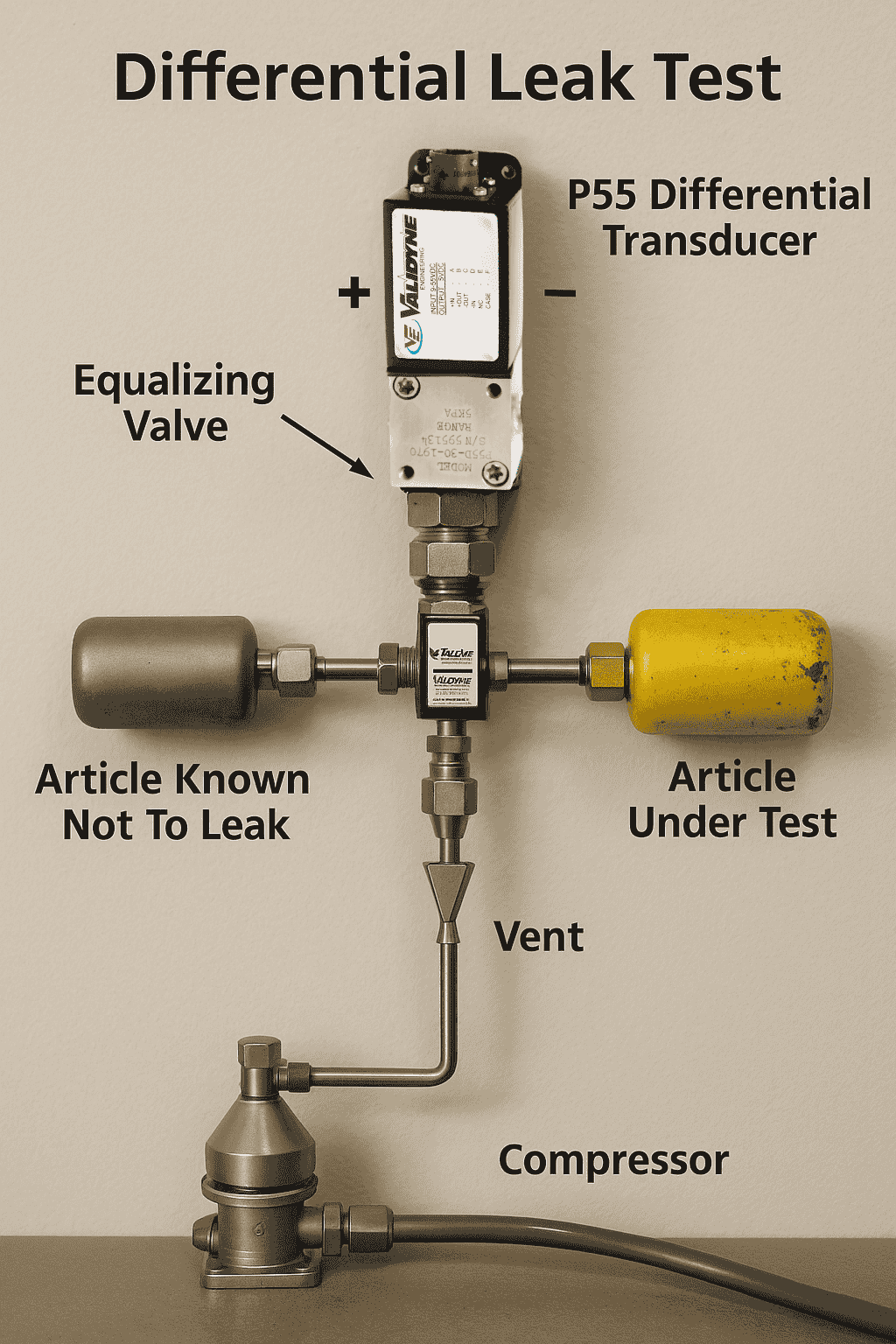

Automotive braking systems are obviously very important and must be thoroughly tested prior to production. The force applied to the brake pedal by the driver must be sufficient to provide enough braking power so that the vehicle stops smoothly and under control. Validyne model P55 differential pressure transducers have been widely used to measure hydraulic pressures in a hydraulic brake system to verify performance.

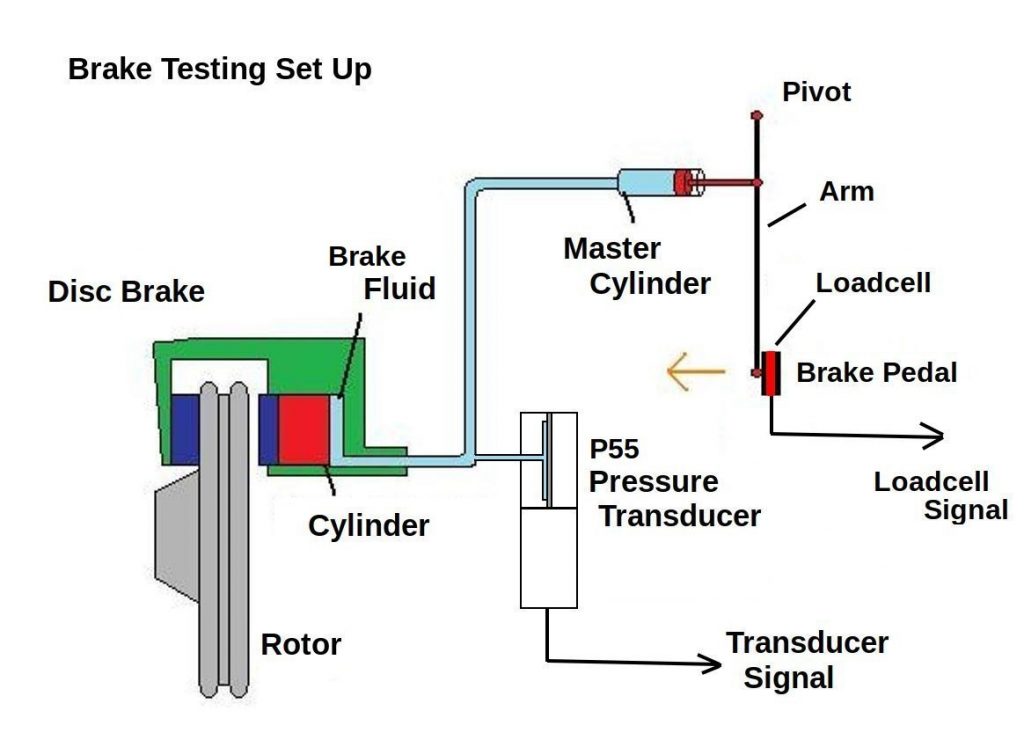

The diagram shows a typical disc brake testing set up. When force is applied by the driver to the brake pedal, it moves forward activating the hydraulic master cylinder. This generates and transmits hydraulic pressure to the brake cylinders on each of the wheel brakes. The brake cylinders move to clamp the spinning brake rotor, which slows and stops the vehicle. The relationship of pedal force to braking pressure is an important parameter. If too much force is required by the driver on the brake pedal, this will result in fatigue and it may not even be possible to drive the vehicle safely. If too much hydraulic pressure is generated by the master cylinder, the vehicle may come to a screeching stop. Power braking and anti-lock systems add to the safety of modern vehicles, but the relationship between pedal force and brake performance is critical regardless of the complexity of the system.

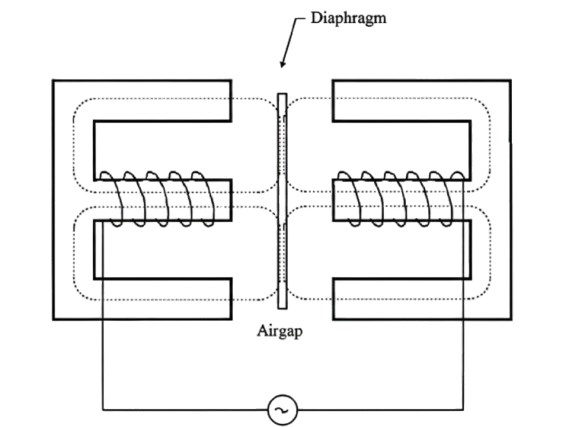

All of this is carefully considered at the design stage by taking into account the master cylinder and brake cylinder diameters, and the pivot moment on the brake pedal arm. Prototype vehicles are often tested to verify braking performance as shown in the diagram. The P55 differential pressure transducer is connected to the hydraulic system to directly measure the pressure generated by the master cylinder. The P55 pressure transducer is ideal for this application because the displacement volume of the sensing element is very small – just a few thousandths of a cubic inch. The small displacement volume of the pressure transducer is important because it does not interfere with the operation of the brake system. The pressure transducer is also compact and rugged so that it can be easily installed on the vehicle and used in a test track environment. The P55 pressure transducer can be ordered with a variety available of sensor o-ring seals that are compatible with standard automotive brake fluids. It also can be ordered with a USB output for easy connection to a computer system or a CANBus output.

A load cell is attached to the brake pedal, and the signal sent to a data acquisition system that records the applied foot pressure along with the resulting system hydraulic pressure as measured by the pressure transducer. The Validyne USB2250 or the USB2251 data acquisition systems allow for multiple input sensors like load cells, thermocouples, pressure transducers and more to be connected to the DAQ in one module. This data is then used to verify the performance of the braking system under various conditions on the test track.

Comments are closed