Aerospace, Utility

Validyne Pressure Sensors: Reliable Performance in Radiation-Exposed Environments

Pressure sensors play a crucial role in industries where accuracy and durability are essential—especially in radiation-heavy environments like nuclear power plants, medical radiation therapy, and high-energy physics laboratories. Among the many sensor brands available, Validyne pressure sensors have consistently proven to be robust, reliable, and resistant to the effects of radiation.

Why Radiation Resistance Matters

Radiation can degrade electronic components, cause sensor drift, and lead to failure over time. Pressure sensors operating in high-radiation environments must be built to withstand:

- Ionizing radiation damage to semiconductor electronics

- Material degradation from prolonged exposure

- Single Event Effects (SEE) that can cause momentary errors or long-term drift

- Calibration shifts over time due to radiation-induced component changes

Validyne pressure sensors have been tested in various studies, demonstrating their reliability and precision even in extreme radiation conditions. Here’s what the research says about their performance.

How Validyne Pressure Sensors Excel in Radiation Environments

Performance in the Large Hadron Collider (LHC) Tunnel

- Despite radiation-induced hysteresis, the sensors remained operational and accurate.

- With appropriate shielding and recalibration, drift effects were manageable.

- The study confirmed that Validyne pressure sensors could be used effectively in high-energy physics experiments.

Long-Term Stability in Nuclear Power Plants

- The sensors demonstrated long-term structural integrity under constant radiation exposure.

- They maintained high measurement accuracy over extended operational cycles.

- Minimal maintenance and recalibration were needed, making them cost-effective for nuclear applications.

Tritium Compatibility for Radioactive Gas Monitoring

- The sealed sensor design prevented leaks, ensuring safe and accurate measurements.

- The sensors remained functional and precise despite prolonged exposure to tritium.

- Ideal for nuclear and industrial gas applications where radiation exposure is inevitable.

Reliable Calibration in Nuclear Facilities

- Even after extended radiation exposure, calibration drift was minimal.

- Their rugged construction made them resistant to environmental degradation.

- The sensors were deemed suitable for long fuel cycles without frequent recalibration.

Precision in Medical Radiation Therapy

- High sensitivity and accuracy made them ideal for patient monitoring in radiotherapy.

- The sensors resisted radiation-induced noise, ensuring reliable measurements.

- Suitable for respiratory monitoring during radiation treatments.

Resilience to Electromagnetic and Microwave Radiation

- Stable and accurate pressure readings despite exposure to high-frequency radiation.

- The robust design allowed them to operate in high-temperature industrial settings.

- Ideal for oil and gas applications where microwave heating is used.

The Best Choice for Radiation-Heavy Applications

Validyne pressure sensors stand out in radiation-exposed environments due to their:

If your industry requires high-precision, radiation-resistant pressure sensors, Validyne is a proven and reliable choice.

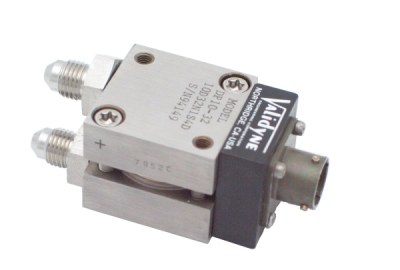

Feel free to view the product page for the DP10 differential welded pressure sensor and the AP10 absolute welded pressure sensor.

You can contact us at sales@validyne.com for more information.

Leave a reply

You must be logged in to post a comment.