Pressure Measurement

Tech Brief: Identifying Transducer Diaphragms

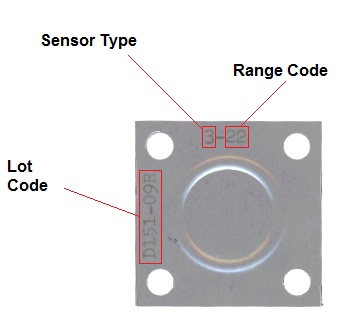

Validyne transducers can be disassembled and the sensing element replaced. This is done to repair an over-pressured sensor or to re-range the transducer for a higher or lower pressure measurement. Validyne transducer diaphragms will have a series of numbers etched on to them that identify their sensor type, pressure range and manufacturing lot code.

As can be seen in the featured image, there are two sets of numbers etched along the top and left-hand edges. The lot code appears on the left edge and is used for production control purposes – it contains no information useful to the user.

The top set of numbers – in this example 3-22 – are the important numbers. The 3 in 3-22 identifies the sensor type into which the diaphragm can be installed. The -22 is the range code and tells what full scale pressure the diaphragm can measure.

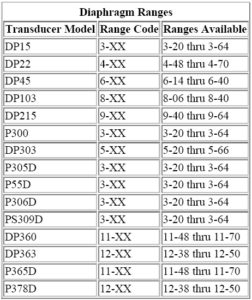

The sensor types and available pressure range codes for each Validyne transducer model are shown in the table below:

The range code pressure chart is shown below:

In the example above, the 3-22 diaphragm can be used in transducer models DP15, P55, PS309, P300, P306 and P305. The -22 range code indicates that this diaphragm has a full scale pressure range of 0.20 psid.

Leave a reply

You must be logged in to post a comment.