Construction, Data Acquisition, Design, Military, Utility

Static Load Structural Testing

Structures that must bear weight or force are tested after construction by applying a static load and measuring the deflection of the structural elements. The deflections must be within permissible limits to verify that the structure can meet the design limits for both static and dynamic loads. This application describes how test loads are applied and how the structural deflections, often very small, are measured and recorded in static load structural testing.

Parking structures are everywhere and we have all used them. Static load structural testing is used to determine if the structure can bear the weight of the parked vehicles and still be strong enough to withstand an earthquake. A typical parking structure consists of a number of different parking levels, or decks, and a roadway that connects them all to the entrance and exit on the ground floor. Parking structures are made from reinforced concrete and each deck must bear the load of the parked cars when filled to capacity. This is especially important in earthquake country, where parking structures have been know to collapse – or ‘pancake’ – when exposed to a strong ground motion and the resulting acceleration. Testing the structural integrity of each deck in the parking structure is an important part of the construction validation process.

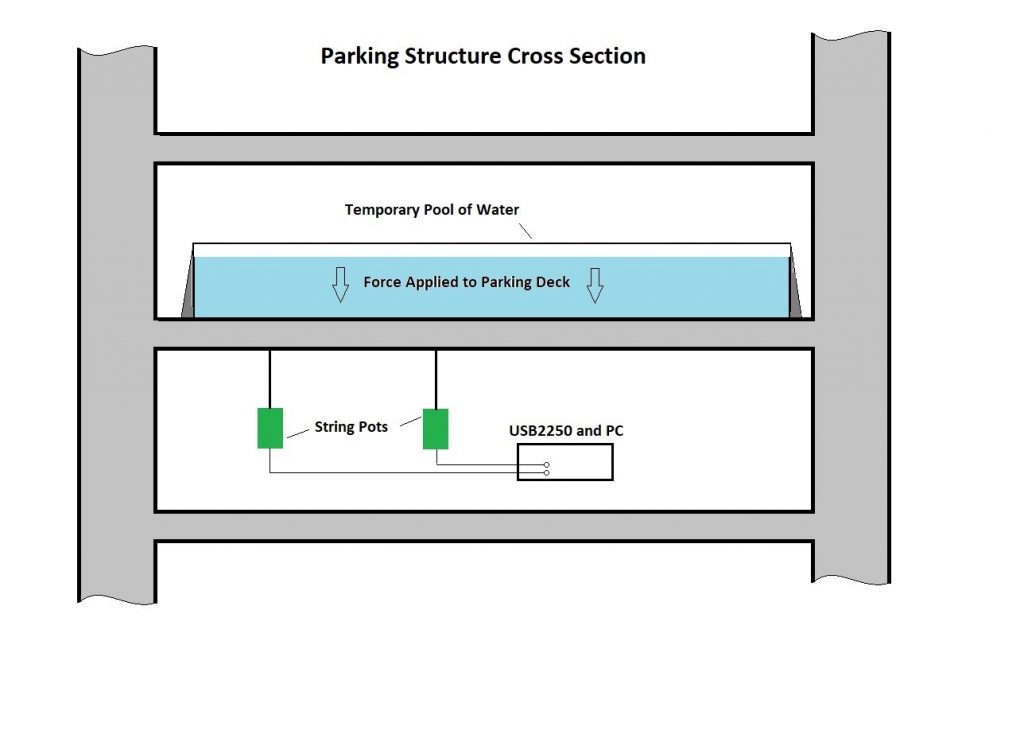

As shown in the diagram above, each deck of a parking structure can be tested with a static load by using a temporary pool of water to apply force over the parking area. A pool can be easily made from large rolls of plastic and some temporary retaining walls. Water weighs 62.4 pounds per cubic foot, so a large pool need not be very deep to apply a large force to the deck structure.

When the pool has been erected and filled to the correct depth with water, the amount of sag and creep is measured over time in order to assess the strength of the deck structure. String pots are connected to the underside of the parking deck at the next level down and wired to a data acquisition system such as the Validyne USB2250. String pots are simply potentiometers that incorporate a coiled spring and cable so that when the cable moves, the voltage output of the string pot changes with displacement. It is similar to a tape measure except that there is an electrical signal that indicates distance instead of a printed tape.

The USB2250 can provide the power to the string pots and scale the voltage signal into units of displacement. The system typically runs a test overnight, recording the string pot readings, time and date every few minutes. At the end of the test time, the movement – or sag – in the parking deck must be within the structural specification. The water pool is then drained and moved to the next deck, where the process is repeated for the next parking level.

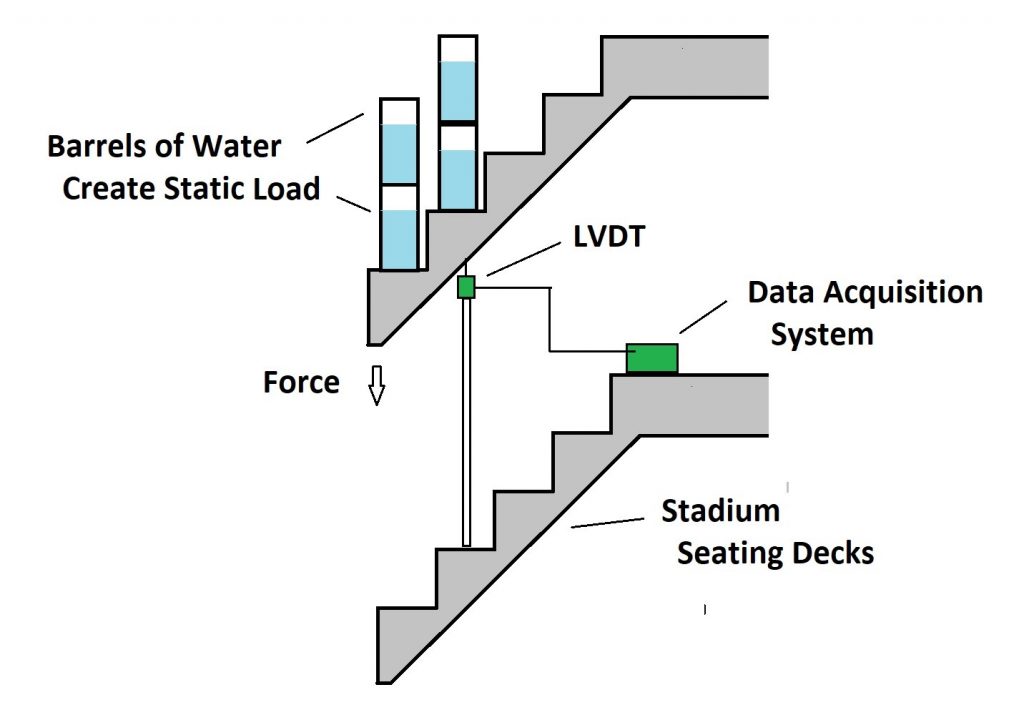

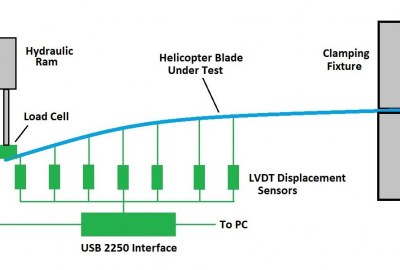

Another type of structure that requires static load structural testing are sports stadiums with over-hanging seating decks. These must be able to take the load of the fans seated during an event, and also withstand a ‘live load’ when people are walking to the exits or jumping up while cheering cheering. Thee test loads are calculated in advance and barrels of water are positioned on the seating surface to simulate the static and dynamic loads. The displacements from these test loads are very small, often just fractions of an inch. To measure this, an array of LVDTs are mounted on support rods and connected to a USB2250 data acquisition system. The load is progressively applied by filling the plastic drums with water. Water meters are used to load the drums to the predetermined volumes. The drums are stacked two or three high to achieve the desired test-loading. The resulting deflections in the structure can be measured and recorded as the load is applied to detect any structural creep or deformation. The diagram below shows how this test is set up.

As with string pots, the USB2250 can interface directly to the LVDT displacement sensors, providing AC excitation, demodulation and conversion to digital reads that can be recorded by a PC. The USB2250 data acquisition system accepts any combination of sensor inputs including thermocouples, RTDs, strain gages, LVDTs, variable reluctance pressure sensors, potentiometers, DC voltage outputs.

More examples of static load structural testing using static loads can be found on-line at https://www.structuremag.org/?p=2594.

if you found this article useful, click here to subscribe to our newsletter for monthly emails with application notes and product solutions. Feel free to contact our sales engineers at sales@validyne.com for more information on the products and solutions in this application note.

Leave a reply

You must be logged in to post a comment.