Pressure Measurement

Stand-Alone Pressure Transducer or Sensor + Electronics?

Validyne pressure transducers break down into two general categories, stand alone or sensor & electronics:

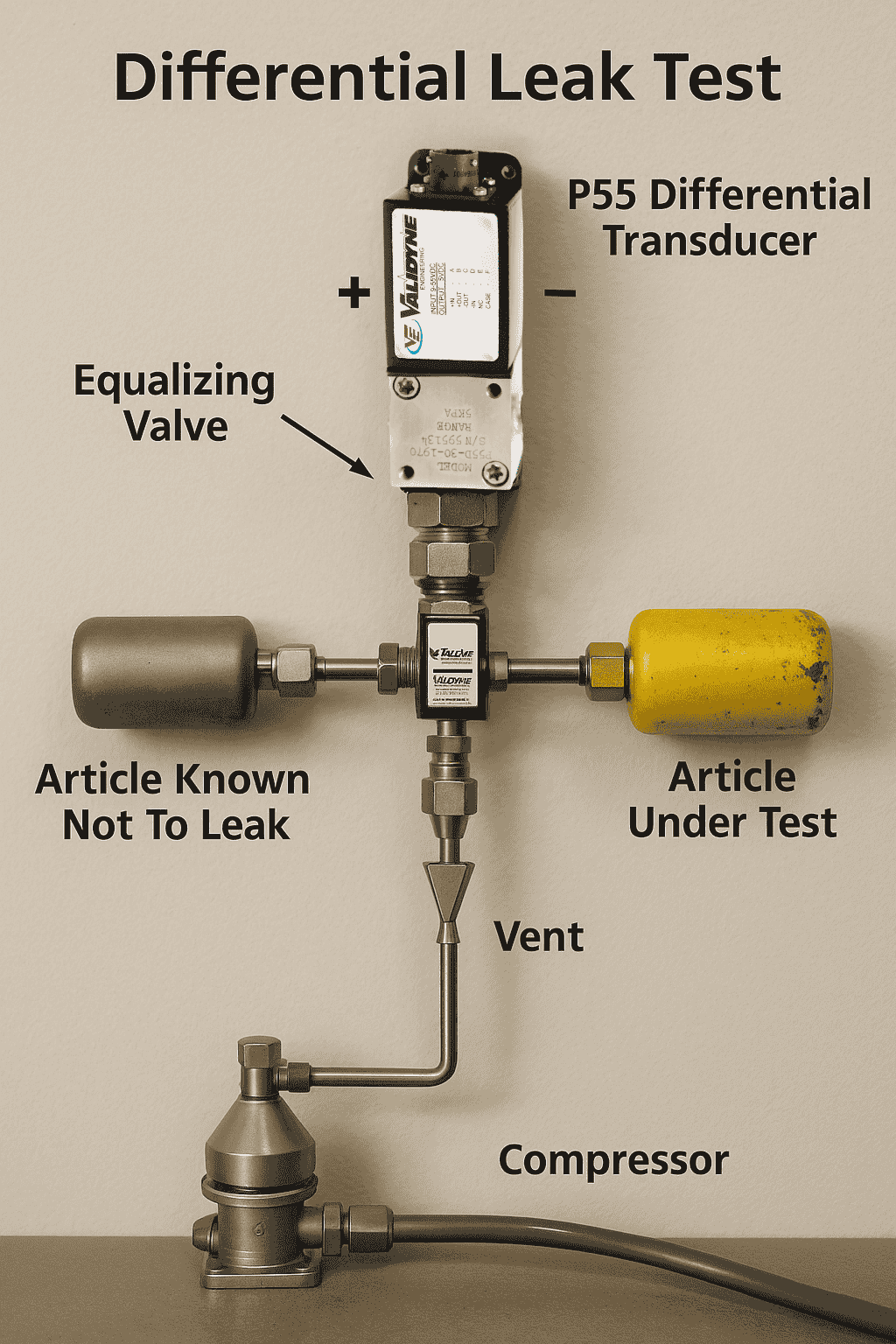

Type 1 – A complete transducer with integral electronics

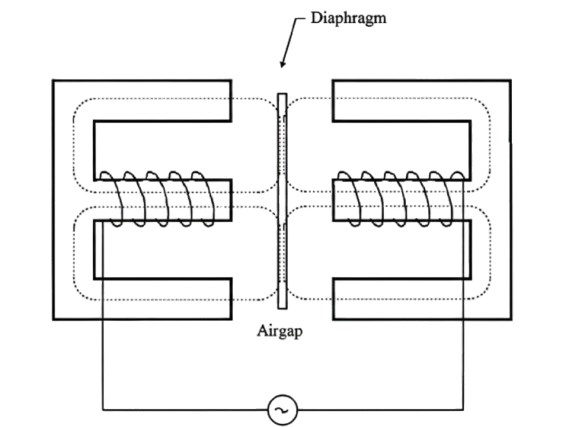

Type 2 – A variable reluctance sensor and supporting carrier demodulator electronics.

Type 1 category products include models P55, P61, P66, the P895 family and the DR800 and P532 process transmitters.

Type 2 category products include models DP15, DP360/363, DP103 with carrier demodulator models CD15, CD23/223, CD280 and CD17.

The transducers in both categories measure the same pressure ranges – so why would you choose one type over another?

Cost Effective DC Power and DC Signal:

Type 1 category transducers are generally more cost effective per point than are the sensor + electronics (Type 2) category. The Type 1 products come ready for DC power and produce a high-level DC signal, +-/5 Vdc or 4-20 mA. The Type 1 transducers include temperature compensation and are also available with higher accuracy because we can program corrections to sensor errors into the microprocessors in these products.

Type 1 products are generally ‘plug and play’ devices and are ideal for permanent installations.

Type 1 (stand alone) products, however, do not lend themselves to the changing of pressure ranges easily. It is possible to disassemble the sensor on a P55, for example, and replace a damaged diaphragm or install a diaphragm with a new range – but the correction factors and temperature compensation in the microprocessor will not be matched to the new assembly. Validyne can do this – and include new temperature compensation and error correction factors – but this takes time and has a cost.

Easy Range Changing:

The biggest reason to use Type 2 products is for convenient range changing. A DP15, for example, will be easier to disassemble and easier to replace a diaphragm than the Type 1 units. The sensor will be easier to calibrate with the zero and span adjustment ranges built into the external carrier demodulators. If fast frequency is important, the smaller variable reluctance sensors can be more conveniently close-coupled to piping than the larger Type 1 units and the electronics supporting Type 2 sensors have a higher low pass filter frequency available – up to 1 Khz.

Type 2 products are best suited to laboratory settings where pressure ranges are frequently changing, where a digital display is needed and where installation flexibility is important.

Type 2 products, however, do not have built-in temperature compensation, must be calibrated by the user with an appropriate pressure standard and are generally more expensive per measurement point.

Comments are closed