Oil & Gas

Soil Consolidation Testing

Introduction:

Soil consolidation testing is used to predict the ability of a certain soil to bear a load safely. Perhaps the most spectacular example of this is the leaning tower of Pisa. Construction was started in the 1173 and the tower took 200 years to complete. During the first 5 years of construction the soft soil on one side of the foundation began to consolidate under the weight of the stone structure and it began to lean. Construction was halted, for a variety of reasons, until 1272 and by this time the soil had stabilized and the rest of the tower was curved to compensate. Eventually, in the late 20th the tower structure was reinforced and remains a famous tourist attraction.

Large buildings today are built on foundation soil that has been tested for compaction before construction begins, and this is why modern buildings that are heavier and taller than the Tower of Pisa can be constructed.

Soil Compaction Testing:

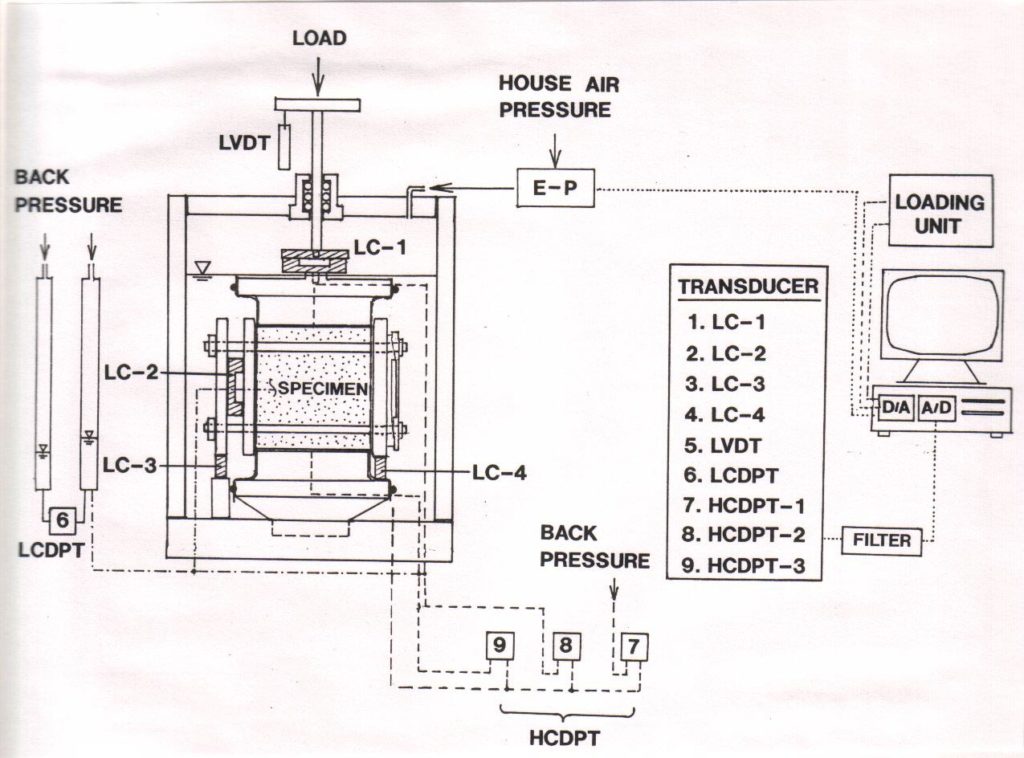

To test soil for unsuitable compaction, a test of several samples is performed in a soils laboratory. The idea is to simulate the conditions of load and water pore pressure in the soil and then measure the amount it compacts, or is compressed under the load. Here is a sketch of a soil compaction test cell.

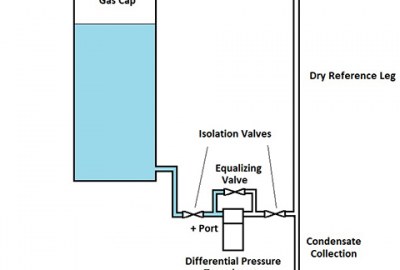

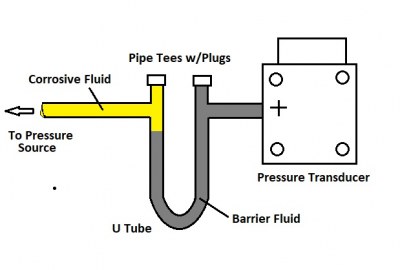

This seems complicated but the idea is that a static load is applied to piston that transmits the force to the soil sample contained within the test cell. Water is introduced and kept to the pressure expected for the construction site and this pressure is sensed and controlled by a pressure transducer. The force of the load is sensed by a series of strain gage load cells and the movement of the sample as it compacts is measured by an LVDT.

A compaction test may take a few hours or several days, depending on the soil conditions and applied load. The idea is to verify that the soil will be strong enough to bear the weight of the building to be built on that particular site.

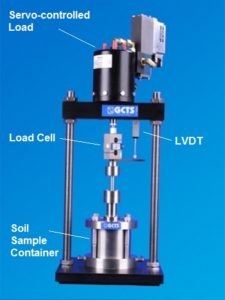

Commercial Soil Compaction Testing System:

In this example a servo-controller is used to apply a continuous load to the sample instead of heavy weights which would make for a bigger and less stable fixture. The load cell just beneath the top platten measures the actual force applied and a spring-loaded LVDT measures the change in thickness of the soil sample as it consolidates.

Validyne pressure transducers are used to measure pore pressures and our USB2250 signal conditioning can be used as the data acquisition interface to record pressure, the force sensed by the load cell and the sample displacement from the LVDT signals. The USB2250 can accept all three sensor types directly, including other sensors such as themocouples and DC voltages. The variety of sensor types used in soil compaction testing – load cells, LVDTs and pressure transducers – make the USB2250 an ideal sensor interface. Validyne will work with customers to integrate the USB2250 into existing soil test software.

Comments are closed