Automotive, University

Reducing Glove Box Filter Costs

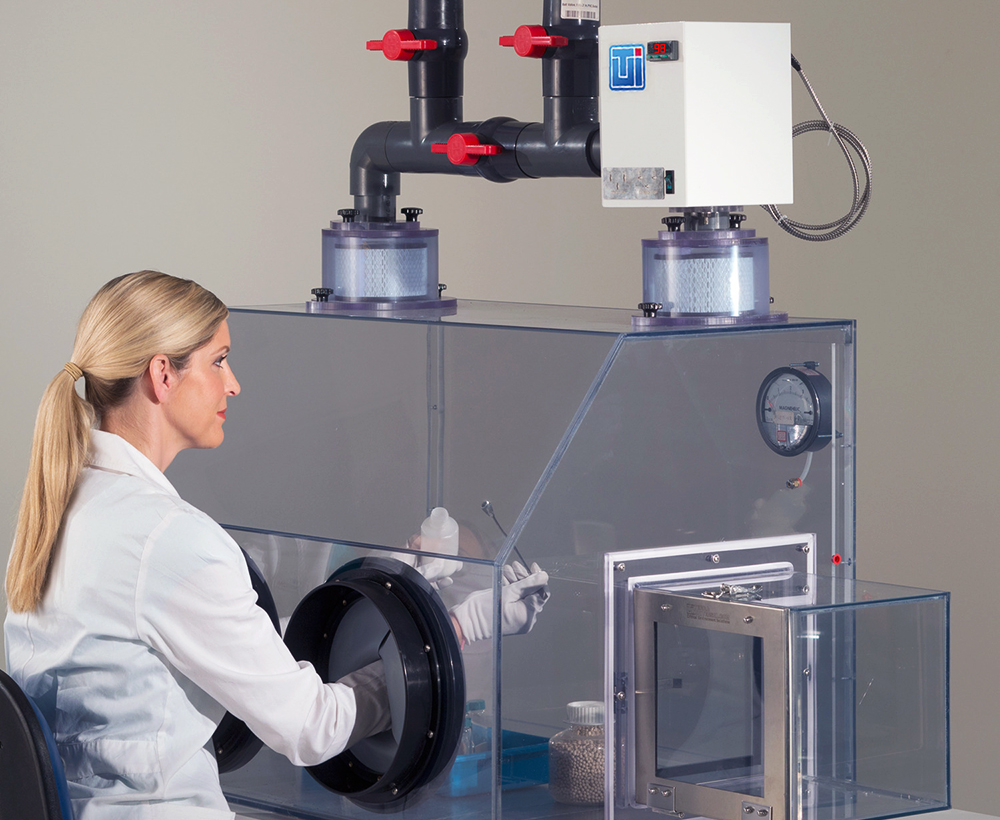

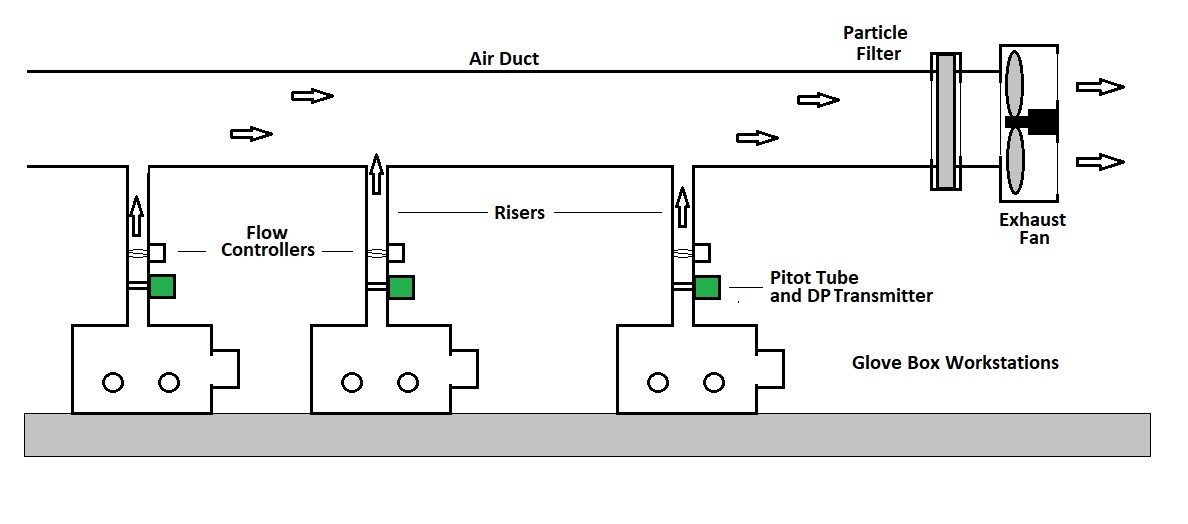

The handling radioactive materials must be done in glove box. A glove box is a clear plastic enclosure with rubber gloves attached to the sides so that an operator can handle the material inside the glove box, but air and radioactive dust are not allowed to escape. The air pressure inside the glove box must be controlled so that it is always less than the ambient atmosphere. A series of risers, ducts, fans and filters connected to the box keeps the pressure inside lower than the outside atmosphere so that no dust can escape. A typical glove box is shown above.

If the airflow velocity up the riser from the glove box is too high, however, radioactive dust is carried into the exhaust system where these particles are trapped by a series of special filters. When a filter needs to be changed, it is charged with radioactive particles. For this reason it must be handled as radioactive waste and is very expensive to remove and dispose. For a large nuclear processing facility, there may be dozens of glove boxes connected to a large network of ducts, fans and filters. The key to reducing filter disposal costs is to limit the exhaust airflow velocity so that dust is not carried up and out of the glove boxes and into the filters, while at the same time insuring that the pressure inside the glove box is always less than the ambient atmosphere. Here is how the air flow system works:

Measurement of the air velocity in the glove box risers is accomplished with a pitot tube and a sensitive differential pressure transducer. As air velocity increases, the differential pressure across the pitot tube increases. The very low velocity needed to exhaust air from the glove box, without raising dust translates into a very low pressure drop across the pitot tube. This pressure drop is as little as 0.02 In H2O under normal operating conditions. A very sensitive differential pressure sensor, combined with a high level DC signal output, is needed to provide the air velocity signal to the system controller.

A special version of the Validyne P532 provides the low pressure measurement required for such a control system and these are used at a major North American nuclear fuel rod processing facility.

Click here to subscribe to our newsletter for monthly emails with application notes and product solutions. Feel free to contact our sales engineers at sales@validyne.com for a pressure measurement solution for your application.

Comments are closed