Carrier Demodulator, Pressure Measurement

Pressure Sensors and External Carrier Demodulators

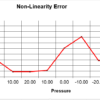

The most popular Validyne pressure transducers are the P55/P61/P365 series. These all include a pressure sensor, carrier demodulator electronics package, a high-level output signal, temperature and linearity correction as well as a compact form factor. There are applications, however, where a better solution might be to separate the pressure sensor from the electronics, using external carrier demodulators connected by a cable. This article describes when this approach makes the most sense.

Validyne offers the sensors and electronics package from the P55/P61 available as stand-alone components. The DP15 series of pressure sensors is identical to that used in the P55 and P61, while the DP360 and DP363 are high pressure variants the same as used in the P365 and P368. The CD16 standard analog output electronics or the CD17 USB-based electronics can be used as external carrier demodulators with any of these sensors, and standard cables are available in a variety of different lengths to connect the two.

When should a sensor be separated from the electronics? The biggest reason to do this is to allow convenient re-ranging of the pressure sensor. The full-scale pressure range of Validyne sensors can be changed by replacing the sensing diaphragm. There are 23 different full-scale ranges available for the DP15, for example, and these run from a few inches of water to 3200 psi. Changing the diaphragm is straightforward; the connector and four body bolts must be removed to gain access to the sensing diaphragm, and the DP15 sensor makes this easy, requiring just a torque wrench and a vise. With a little practice, the diaphragm in a DP15 can be replaced and re-calibrated with the CD16 or CD17 electronics in about 20 minutes. The DP360 and DP363 high pressure sensors are similar in construction and also lend themselves to straightforward diaphragm replacement. Frequent re-ranging of the full scale of a Validyne transducer is common in laboratory situations where pressure measurements vary widely from day to day. Test labs and university labs are typical places where a separate sensor and electronics package are used to best advantage.

Another reason for separating the pressure sensor from the electronics is to conserve space or limit the weight at the measurement point. In tight locations, such as aircraft compartments or in submersible vehicles, the pressure connection may be in a relatively inaccessible space and the smaller footprint of the DP15 sensor, might fit better than the full P55. If mass or weight is important, the sensor will be lighter than the full transducer and this will relieve any stress on the piping connections in areas where shock and vibration are a consideration.

It is important to realize that separating the sensor from the electronics will compromise the temperature correction as the temperature sensor is located on the electronics package and not at the pressure sensor. A pressure sensor such as a DP15 used with remote electronics such as the CD16 will be most effective in applications having a stable temperature environment.

Comments are closed