Precision Viscometry

Precision Viscometry Using Hydraulic Bridge

If you are making complex molecules, how do you know your process is on target? Many petrochemical products contain long polymer chains that can change character quickly with only small deviations in the manufacturing process. Modern pharmaceuticals now include complex proteins and other molecules that are difficult to characterize by conventional methods. How can you be sure your thousand tons of plastic sheeting or that new wonder drug is going to meet spec? One tool to determine the nature of complex molecules is a precision viscometer.

Viscosity is the internal resistance of a fluid to flow. Complex molecules typically interact with each other in a fluid and this can cause telling changes in viscosity. A polymer molecule in one state may have little interaction with its neighbors, and so its characteristic viscosity is low. In another state, the same polymer may interact strongly, and the resulting viscosity will be much higher. Measuring viscosity is often a reliable way to determine the state of complex molecules in a manufacturing process. The precision viscometer is an important analytical tool in both research and production.

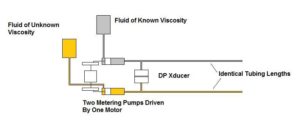

A fluid bridge is used to create a viscometer that is highly sensitive to small changes in product viscosity. A dual metering pump is used to pump two fluids along equal lengths of precision tubing. One side of the pump pushes a fluid of known viscosity. The other side of the pump pushes the test fluid along an identical length of tubing at precisely the same rate as the reference fluid. The difference in back pressure due to flow is a measure of the difference in the viscosity of the two fluids. Because one fluid has a known viscosity, the pressure difference observed between the two lengths of tubing can be used to determine viscosity of the test fluid. The differential pressure transducer is plumbed between the two tubes so that the back pressure difference due to fluid flow is measured directly.

A complete precision viscometer includes the pump, tubing, transducer and a computer that calculates the viscosity and displays a plot on the screen. These analyzers are often used in conjunction with an liquid chromatography column that fractionates polymers at various temperatures. As these fractions appear in the unknown fluid stream the viscosity is a good indication of the size and character of the polymer fraction.

Validyne provides the differential transducer that includes special chromatographic pressure fittings in the sensor body. The very low displacement of the transducer is ideal for use in these systems where dead volume is a source of measurement error.

P55 with special chromatographic pressure fitting

(Option G under Pressure Port – Ordering Information)

P81 with 1/16″ pressure port

The latest Validyne sensor for precision viscometry – model P81 – features a 316 SS sensor body that allows use in aqueous solutions typical in pharmaceutical and food processing applications. Contact our sales department at sales@validyne.com or at 818-886-8488 for more information on these options.

Comments are closed