Oil & Gas, Utility

Petroleum Core Testing

How much oil will come out of an oil field? Is it worth developing once it is discovered? These are not trivial questions if you must drill and complete your wells in deep water offshore or on the remote North Slope of Alaska. All of the major oil companies maintain core testing labs whose job it is to evaluate the oil producing potential of a given field based on the evaluation of oil cores. An oil core is a sample of the oil-bearing rock as obtained from exploratory drilling. The idea is to subject the recovered core to down-hole temperatures and pressures, then measure the flow of fluids through it. Oil producing rock typically has the density and porosity of cement, so the study of fluid flow in these materials requires the ability to measure small differential pressures (just a few psi) at very high static pressures (several thousand psi).

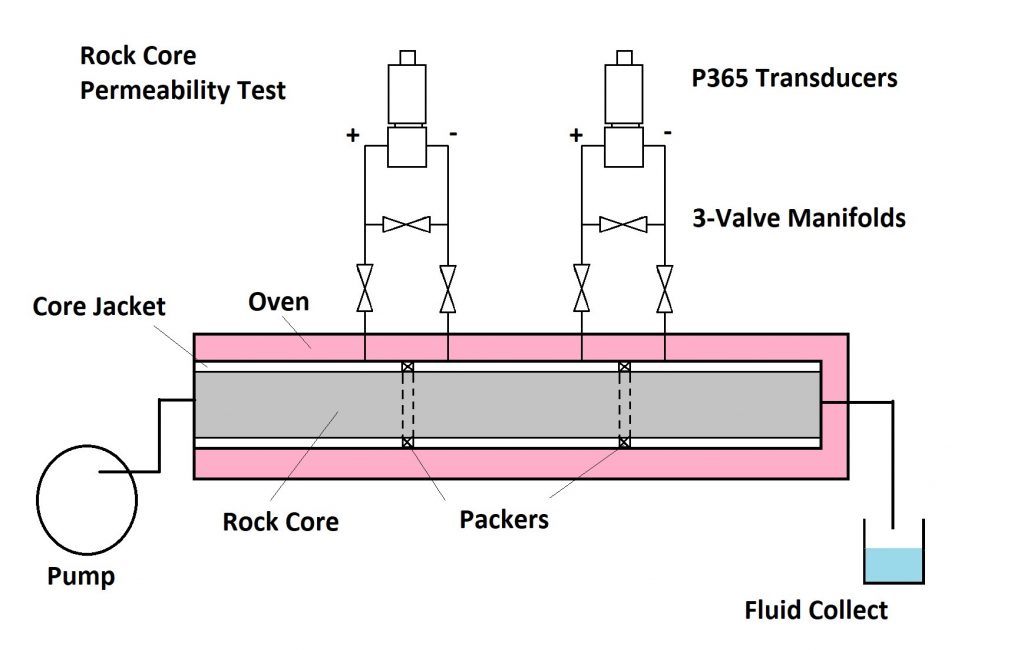

The oil core is prepared by fitting it into a special jacket that is heated to down-hole temperature. A special high-pressure pump forces brine through the core. The static pressures around the core are typically 5000 to 10,000 psig.

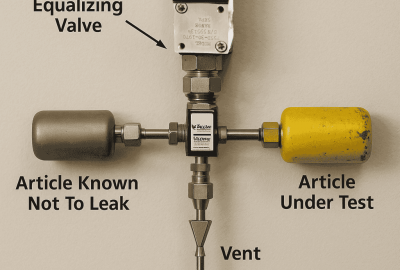

As seen in the diagram, the core has sealing packers placed along its length at regular intervals. A Validyne variable reluctance pressure transducer like the P365 high line pressure transducer is plumbed between the packed-off sections so that the pressure drop through the core rock as a function of flow rate can be measured. Three-valve manifolds are used to protect the P365 high line pressure transducer from over-pressure. The pressure drop through the rock core may be very slight – just a few psi. The P365 high line pressure transducer can withstand the high static pressures within the core while measuring the small pressure drops along the length of the core as fluid moves through it. The fluid is collected at the outlet of the core jacket and measured to determine the flow rate.

Validyne offers several models of pressure transducer that have a full scale of little as 5 psi of differential pressure, while both ports of the transducer are at a static pressure of 10,000 psig. A carrier demodulator displays the differential pressure digitally in engineering units. The relationship between flow and pressure drop is part of the calculation for the permeability of the oil producing formation, and this can be used to determine the amount of oil that can ultimately be brought into the well bore from the surrounding rock, and produced at the wellhead.

Comments are closed