Oil & Gas, Utility

P61 USB Pressure Transducer Used in Petroleum Research

Introduction:

When an oil field is first drilled and brought into production something like 85% of the oil typically never gets to the well bore because of the low porosity and permeability of the reservoir rock. Secondary recovery methods are employed to enhance oil production from existing wells to extend the economic life of the oil field. This often involves injecting natural gas back into the rock formation to build the pressure that will drive the oil to the well bore, and to sweep unrecovered oil from the tiny pores inside the rock.

There is much petroleum research devoted to this subject including a theoretical effort to describe those secondary techniques that are most effective. The problem is that reservoir rock is created by nature and all differ in some degree from the ideal. One way to research secondary recovery on a theoretical level is to create small samples of simulated reservoir rocks using semiconductor micro-machining techniques. In this way a thin slice of ‘rock’ can be created that has a theoretically ideal geometry and porosity. In this way secondary recovery techniques can be tested and observed on a micro level.

Simulating Ideal Reservoir Rocks:

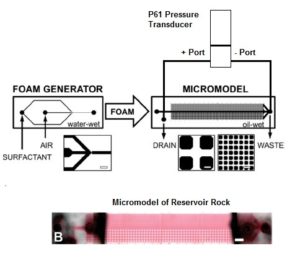

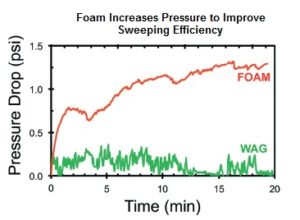

A typical set up is shown below. Small squares are machined into a this sample to simulate the reservoir rock. Natural gas and various surfactants are pumped as a foam through the sample and the process recorded by video and pressure measurement. At one laboratory the Validyne P61 USB Pressure Transducer was used to measure the pressure drop across the sample as the foam is introduced. The idea is that by using a foam instead of just natural gas, the pressures and sweeping efficiency will be increased. This can be tested on a micro scale for an ideal slice of rock, and the results extrapolated to actual field conditions.

The P61 USB Pressure Transducer can measure low pressures effectively and connects directly to the PC data acquisition system via a USB port. The virtual serial COM port for the P61 is easy to integrate into data acquisition software, in this case MATLAB. The pressure drop across the sample is one indication of how effective the foam will be when used to increase oil production by secondary techniques.

Comments are closed