Aerospace, Automotive, Flight Testing, Military, Oil & Gas

Fluid Isolation in Pressure Transducers for Corrosion Protection

When the chemicals present in a fluid are very aggressive, and the pressure transducer is not available in materials sufficiently resistant to corrosion, it is often possible to mitigate these conditions with a fluid isolation system. This system can be created from easily available parts and help to achieve a useful service life where rapid damage of the pressure transducer would otherwise occur.

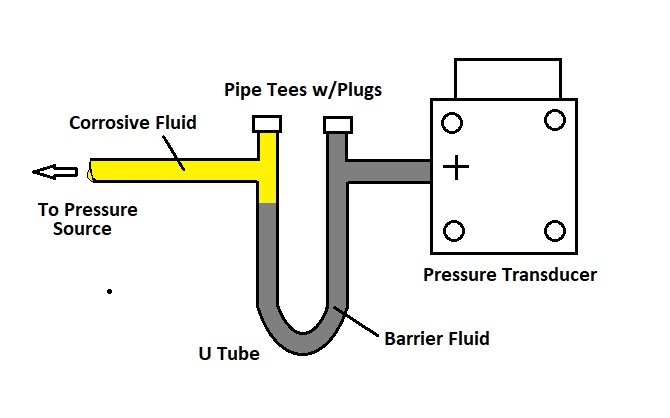

The concept is simple: create a liquid barrier to the corrosive fluid in the tubing leading into the transducer pressure ports. The barrier fluid can be captured in a U tube placed just before the transducer inlet so that it is trapped in place. The barrier fluid transmits the hydraulic pressure to the transducer, but because there is no flow, it acts as a buffer against the corrosive liquids in the rest of the system.

There are a few considerations to keep in mind. The barrier fluid must be compatible with the fluid in the rest of the system or it will represent an undesirable contaminate. The barrier fluid must also be stable and inert so that it does not represent a corrosive threat to the transducer. A thick, viscous mineral oil is often used in systems where brine is present – this will tend to stay in place inside the U tube and is compatible with both the transducer and other fluids in the system. The selection of the best barrier fluid is often a process of experimentation and some knowledge of how it will affect the rest of the system is critical.

Leave a reply

You must be logged in to post a comment.