Automotive, Data Acquisition

DAQ Used in Climatic Wind Tunnel for Vehicle Testing

A new model automobile must be thoroughly tested in climate extremes before it is put into production. Will the heater keep the passengers warm in a blizzard? Will the cabin be cool enough in the desert summer? Can the engine cope with temperature extremes? Auto manufacturers now answer all of these questions by placing a new prototype automobile in a climatic wind tunnel (What is a Wind Tunnel? – External Link (NASA)).

A climatic wind tunnel is a system that can produce all the expected extremes of temperature, wind, sun, rain and snow on demand. In years past new vehicles were tested in very hot weather like at Tuscon, Arizona in July and in cold weather like at International Falls, Minnesota in February to naturally experience the climate extremes needed for verifying vehicle performance. But the design cycle for new vehicles is much shorter now and the climatic wind tunnel can supply these extremes on demand without the need to wait for a particular season of the year.

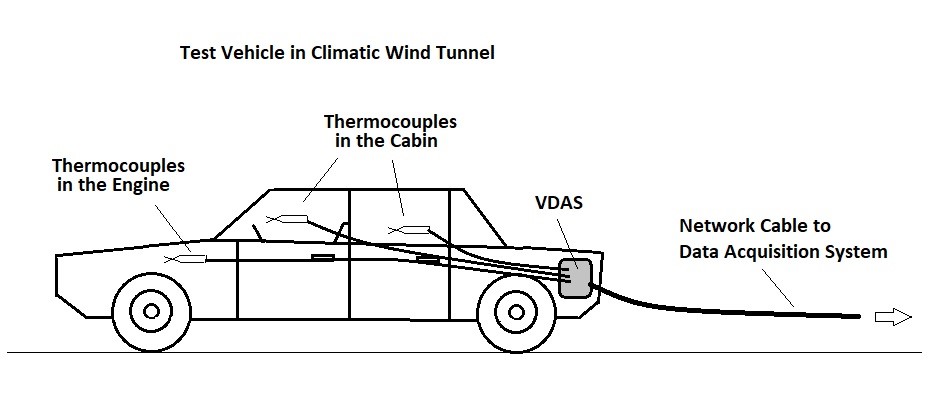

Vehicles tested in a climatic wind tunnel are fitted with dozens of thermocouples placed all around the passenger cabin and in the engine compartment. As the vehicle is exposed to extremes in temperature, the heating and cooling systems are tested and the various temperatures recorded by a data acquisition system. Thermocouples are used because they are relatively inexpensive and can be small enough to have fast response times to rapid changes in temperature. But thermocouple sensors have a low level signal, are non-linear and require temperature compensation for the connecting junction. Validyne Engineering developed the Vehicle Data Acquisition System (VDAS) to meet all of the technical requirements of using large numbers of thermocouples accurately for climatic wind tunnel testing.

The VDAS can accept up to 300 thermocouples and provides amplification, linearization, digital conversion and reference junction temperature compensation on a channel-by-channel basis to provide accurate temperature readings. Real-time temperatures are sent to a data acquisition system via a single network cable using TCP/IP protocol. The VDAS is small enough to fit in the trunk of the test vehicle will run on 12 Vdc vehicle power.

The diagram shows a simplified VDAS installation. In cold weather testing, the VDAS records the temperature readings from thermocouples placed all around the passenger cabin. As the vehicle heater is turned on, the resulting cabin warm up times and temperatures can be checked for passenger comfort. In hot weather testing, the vehicle air conditioning system is similarly measured. Engine temperatures during hot and cold extremes are also measured to be verify performance and reliability.

The VDAS allows the vehicle to be fitted with thermocouples in the instrument shop and rolled into the climatic wind tunnel for immediate testing. The cost of operating a wind tunnel facility is significant, and with the VDAS there is little or no downtime needed to install thermocouples before or during the test. This greatly increases the productivity of climatic wind tunnel testing, saving both time and money in the vehicle development process.

Validyne can provide further details and VDAS specifications on request.

VDAS – 8 Slots

Comments are closed