Automotive

Car Door Seal Testing

We sometimes notice that when we get inside a car there is a short pressure rise inside the cabin when the door is slammed. We feel this as pressure on our ear drums. A pressure rise is an important test during automobile design and assembly because when the cabin can hold pressure it is proof that the door seal is functioning correctly and that the surfaces of the door and frame are mating perfectly. It is also a test of how well the windows are sealing and also the general fit and assembly of the body. To measure the pressure, rise inside the passenger cabin, one auto manufacturer selected the Validyne DP45 pressure sensor because of its sensitivity to low pressures and fast dynamic response, making it ideal for evaluating door seal integrity.

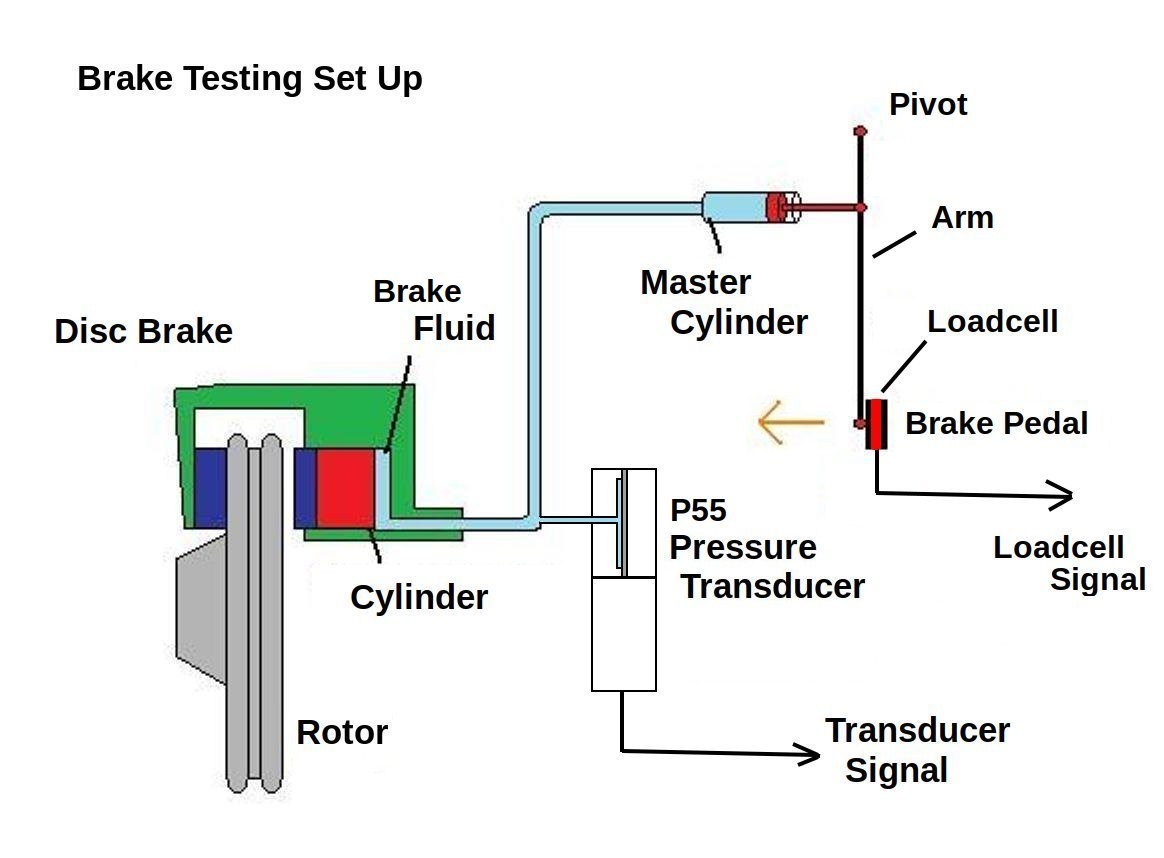

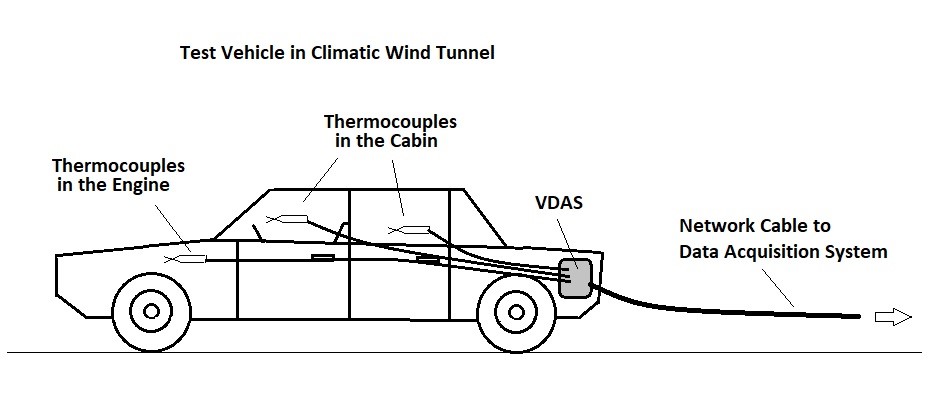

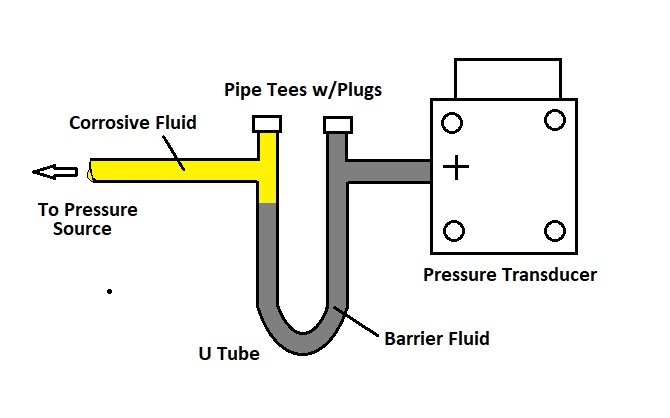

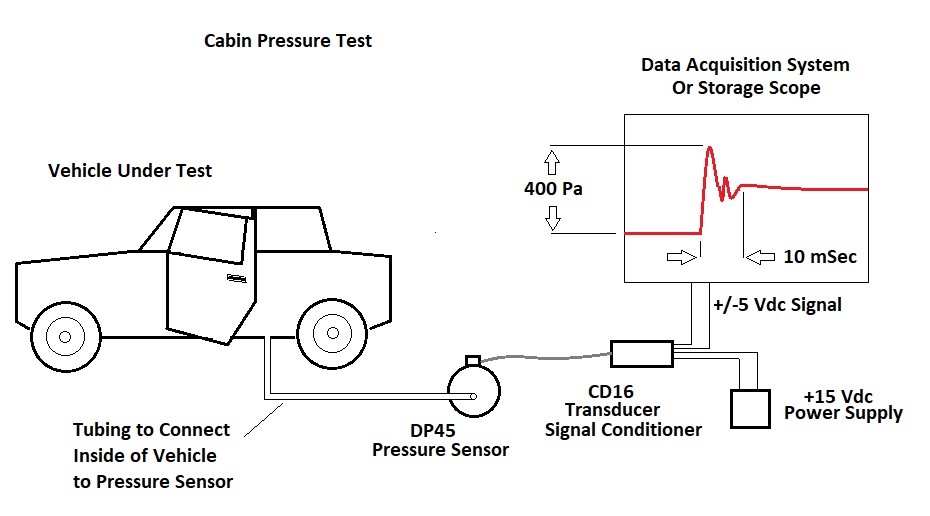

The diagram shows how this was accomplished. The Validyne DP45 pressure sensor’s positive pressure port was connected to the inside of the vehicle under test with a short length of plastic tubing. The pressure sensor was connected by cable to the Validyne model CD16 signal conditioner which provided the pressure sensor excitation and amplification of the signal, calibrated to ±5 Vdc over a known pressure range. The CD16 carrier demodulator was powered by a common +15 Vdc power supply and the signal sent to a data acquisition system. When the car door was slammed, a pressure rise of some 400 Pascals was measured over the 10 mSec duration of the transient. The pressure rise verified that the door seal was functioning correctly and yet would not be uncomfortable for the passengers inside.

The Validyne DP45 pressure sensor is available in full scale ranges as low as 220 Pa and has a flat dynamic response on the order of 60 Hz and can thus capture transients whose rise time is on the order of 4 mSec.

The car door test system is comprised of the following Validyne Models:

- DP45-18-A-1-S-4-D Pressure Sensor

- CD16-A-1-A Carrier Demodulator

- 1280-1002 Mating Electrical Connector

- Cal-B2 – System Calibration for 0 to 400 Pa = 0 to +5 Vdc

The system calibration is convenient to the user because of the low pressures involved – we calibrate the system at Validyne prior to shipment. The customer attaches DC power (9 to 55 Vdc) to the connector and also the 0 to +5 Vdc signal wires to a high speed data acquisition system. The sensor has 1/8” female NPT ports and these are fitted with tubing adapters by the customer to plastic tubing that is run to the inside of the automobile passenger cabin.

Variable reluctance pressure sensors like the DP45 are sensitive to low pressures because the internal sensing diaphragm is large enough to detect very small pressure changes and will produce a high-level signal inductively. Variable reluctance sensors have fast dynamic response because the only moving part is the flat sensing diaphragm – there are no linkages or other mechanical connections to slow down response.

Comments are closed