Pressure Measurement

Application Note: Selecting O-Ring Material

Validyne transducers and sensors bolt together around the sensing diaphragm. In order to seal the sensor cavity so that pressure can be measured, O-Ring seals are used. The O-Rings come in contact with the fluid inside the transducer so it is important that the fluid and the O-Rings are compatible. Various O-Ring compounds may be specified in the transducer model number to insure that the seal will remain viable when in contact with the fluid during service. This application note will discuss how to select the best O-Ring material for your application.

The standard O-Ring material used in Validyne transducers is Buna-N. This compound is compatible with water, oil and most gases. Since most fluids involved in pressure measurement are usually water or oil-based, Buna-N is normally sufficient. But if you are not sure, it is best to check a compatibility table to select the best O-Ring compound.

The industry standard reference for O-Ring fluid compatibility is the Parker O-Ring Handbook, as published by Parker-Hannifin, manufacturers of O-Rings and fittings. The O-Ring Handbook has an extensive set of tables that give the compatibility of various O-Ring compounds with chemicals commonly used in industry. The O-Ring Handbook is now accessible on line at:

To use the Parker compatibility tables simply look up the chemical or fluid in question (they are given alphabetically) and determine the compatibility rating of the various available O-Ring compounds.

The Validyne transducer model number designations for the available O-Ring compounds are as follows:

| Validyne Model | Common Term | Parker O-Ring Book Designation |

|---|---|---|

| N | Buna-N | Nitrile |

| E | Ethylene Propylene | Ethylene Propylene EPDM |

| S | Silicone | Silicone MQ |

| T | Teflon | Not Offered by Parker |

| V | Viton-A | Fluorocarbon |

| K | Kalrez | Fluorosilicone |

The compatibility designation in the Parker book is 1 through 4 where 1 is considered compatible and 4 is considered unsatisfactory.

Here are some examples:

Fluid: Carbon Dioxide

Compatibility: All of the O-Ring compounds are shown as compatible – Buna-N is a good choice.

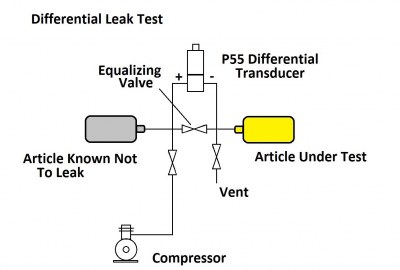

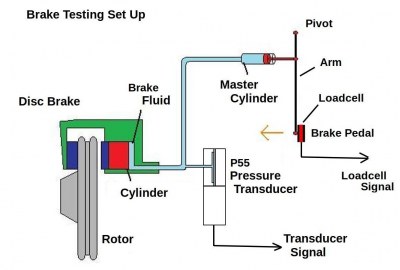

Fluid: Brake Fluid DOT 4

Compatibility: Ethylene Propylene is the best choice as it is compatible with the fluid and available as a selection in the Validyne model number.

Fluid: Dichlorobenzene

Compatibility: Fluorocarbon is given as compatible in the Parker table and so Viton-A should be chosen in the Validyne model number. Note that the Parker book shows two different dichlorobenzene compounds, but both are compatible with fluorocarbon.

Teflon is normally a good choice for compatibility with all kinds of fluids but we have found that the lack of elasticity in a teflon O-Ring can cause issues with transducer accuracy and performance. Teflon has a tendency to cold flow over time and this affects the clamping force on the transducer sensing diaphragm. An O-Ring with elasticity is always the better choice and a satisfactory compound can usually be found for all but the most corrosive of fluids.

If the O-Ring in the sensor is not compatible with the fluid, the first sign will probably be leaking or even complete loss of pressure. Disassemble the sensor and inspect the O-Rings for swelling and replace with a compatible compound. Validyne offers O-Rings separately for each model transducer or sensor and these are usually in stock. You can find more details on O-Rings here.

Leave a reply

You must be logged in to post a comment.