Data Acquisition, University

Connecting Strain Gages to the USB2250, Part II

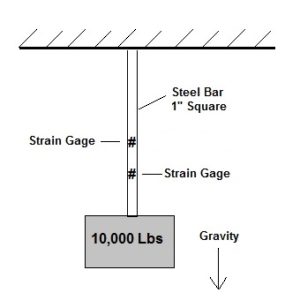

The quarter-bridge strain gage configuration can be improved upon to increase the output signal into the USB2250 by adding another strain gage to the system. For the previous example, the second strain gage could be affixed to another part of the steel bar, as shown below.

The applied load and stress are the same as before, so the two strain gages will change in resistance by the same amount.

dR = Rsg * GF * E

Where:

dR = Change in resistance of the strain gage, Ohms

Rsg = nominal resistance of the strain gage, Ohms

GF = Gage Factor of the strain gage (stated by the manufacturer but usually about 2)

E = Strain, inches/inch

Assuming a gage factor of 2, the change in resistance in Ohms = 350 * 2 * 3.333 e-4 = 0.233 Ohms for each gage.

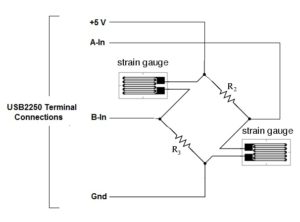

Because there are two strain gages we can construct a half-bridge circuit that will double the signal going into the USB2250:

The output of the bridges is now doubled.

In the example the strain gage resistance has changed from 350 Ohms at no load to 350.233 Ohms when 10,000 pounds is applied to the bar. The output signal of the Whetstone half-bridge is calculated as follows:

Vb = ((Ve * Rsg)/(R2 + Rsg)) – (Ve * R3)/(R3 + Rsg) = 0.0016637

Where:

Vb = voltage output of the bridge, Vdc

Ve = USB2250 excitation voltage, Vdc = 5

Rsg = Rsistance of the strain gages, Ohms = 350.233

R2 = Completion resistor, Ohms = 350

R3 = Completion resistor, Ohms = 350

So the circuit now produces 1.6637 millivolts at full load.

We can also express that as millivolts output per volt of excitation, or mV/V:

mV/V = 1000 * (Vb/Ve) = 0.33274

So the USB2250 will receive 0 to 0.33274 mV/V of signal from this circuit as the bar is loaded from 0 to 10,000 lbs.

To determine the scale factor for the USB2250 that will indicate applied load, we proceed as before:

Lb = mV/V * SF

Where:

Lb = Applied force in pounds

mV/V = signal from Whetstone bridge

SF = Scale Factor

Re-arranging this we get SF = Lb/mV.V = 10000/0.33274 = 30053

By entering 30053 into the Scale Factor box in the USB2250 software, we will now receive the readings as pounds of force applied to the bar.

Twice the signal coming from the strain gage circuit means that any noise present will be less of the total available signal. Because strain gages have such a small output, any chance to increase the signal should be implemented.

Comments are closed