Aerospace, Oil & Gas, Utility

Temperature Isolation of Pressure Sensors

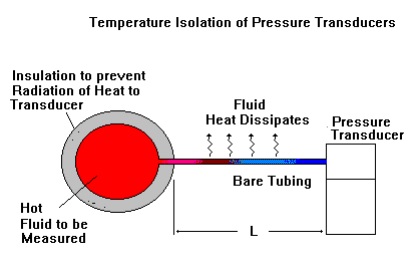

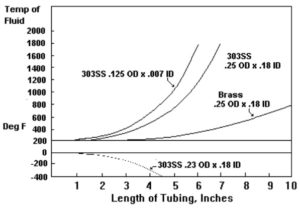

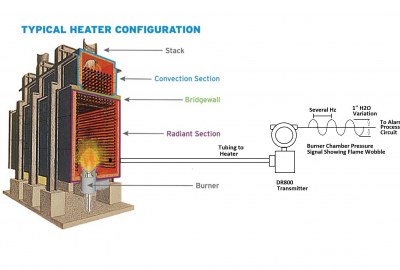

Frequently it is necessary to measure the pressure of fluids which at temperatures above or below the rated operating range of the available pressure transducers. The expense of a special transducer can often be avoided if the pressure sensor is isolated from the pressure source by a short length of pipe or tubing. See how Temperature Isolation can help improve the data you are looking for.

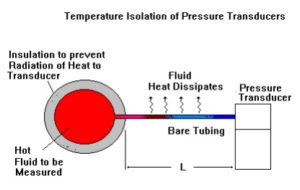

The graph below shows the lengths of tubing needed to limit the temperature at the transducer to a range of 0 deg F to 200 deg F for fluid temperatures between -400 deg F and +1700 deg F. The curves are based on the following assumptions:

- The piping is insulated to limit radiant heat transfer to the transducer. The major source of thermal input to the sensor is by conduction through the connecting tubing.

- The pressure media has a coeffieicnt of thermal conductivity less than 0.4 BTU/hr/ft/deg F. This includes a wide range of liquids and gases.

- The ambient air temperature around the transducer is not greater than 100 deg F.

- The heat transfer rate from the bare tubing to still air is 1.44 BTU/sq ft/hr/deg F.

There is no flow of fluid through the tubing to the transducer, therefore the only path for heat transfer is conduction. Because the tubing is not insulated and the ambient air temperature is less than 100 deg F, the heat dissipation of the tubing protects the transducer, even to extremes in temperature of the fluid to be measured.

Comments are closed