Pressure Measurement

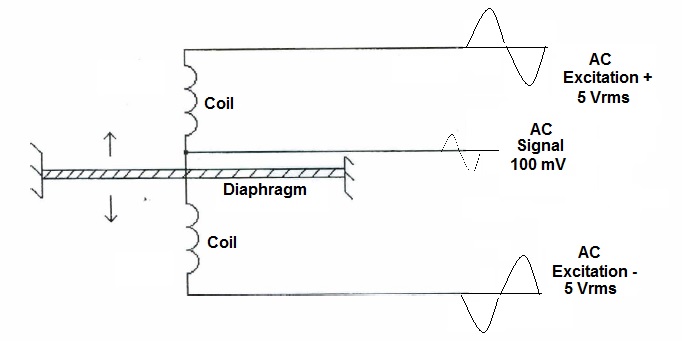

What is the Meaning of Signal Output in mV/V?

Validyne variable reluctance sensors such as the DP15 Pressure Sensor, DP103 Low Pressure Sensor, DP360 High Pressure Sensor, etc all have signal output(s) specified in ‘millivolts per volt’ or mV/V. What does this…

Read More