Pressure Measurement, Utility

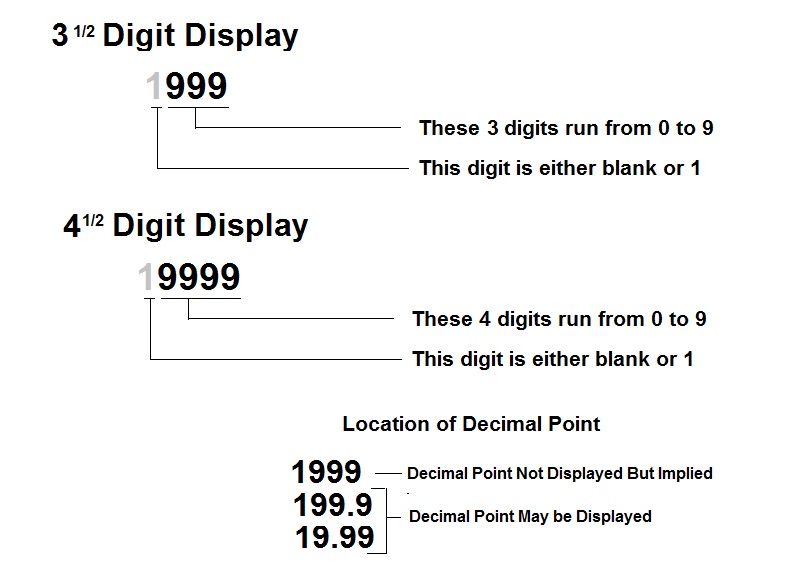

Understanding Digital Displays

Digital display specifications can be confusing. Here is a short application note that describes the terminology and capabilities of a digital display. Digital displays are specified as being either 3-1/2…

Read More