Pressure Measurement, Utility

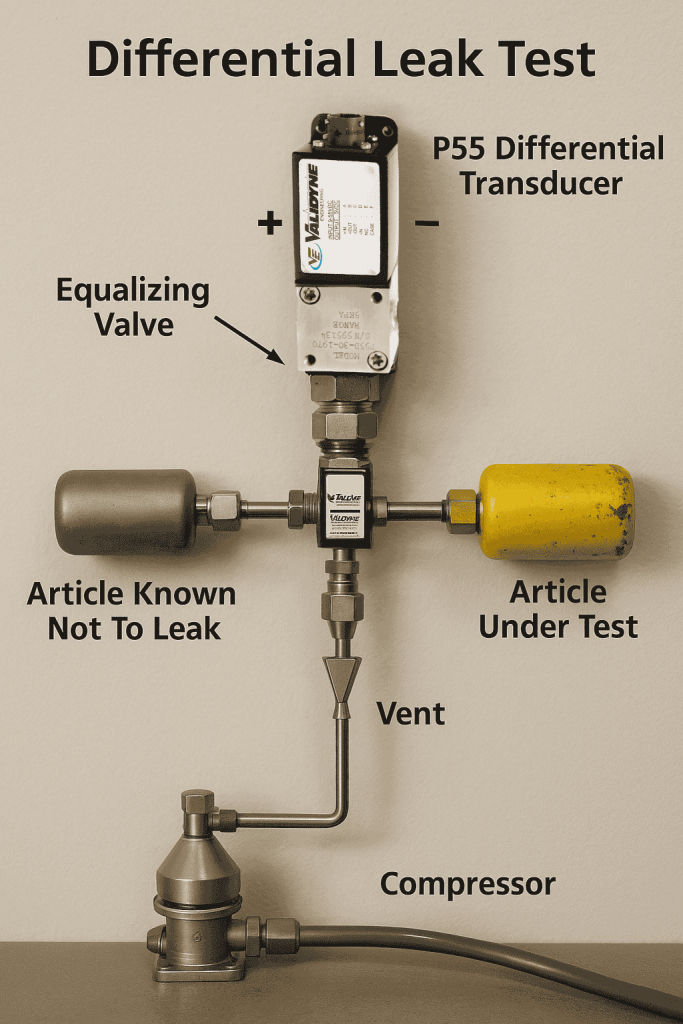

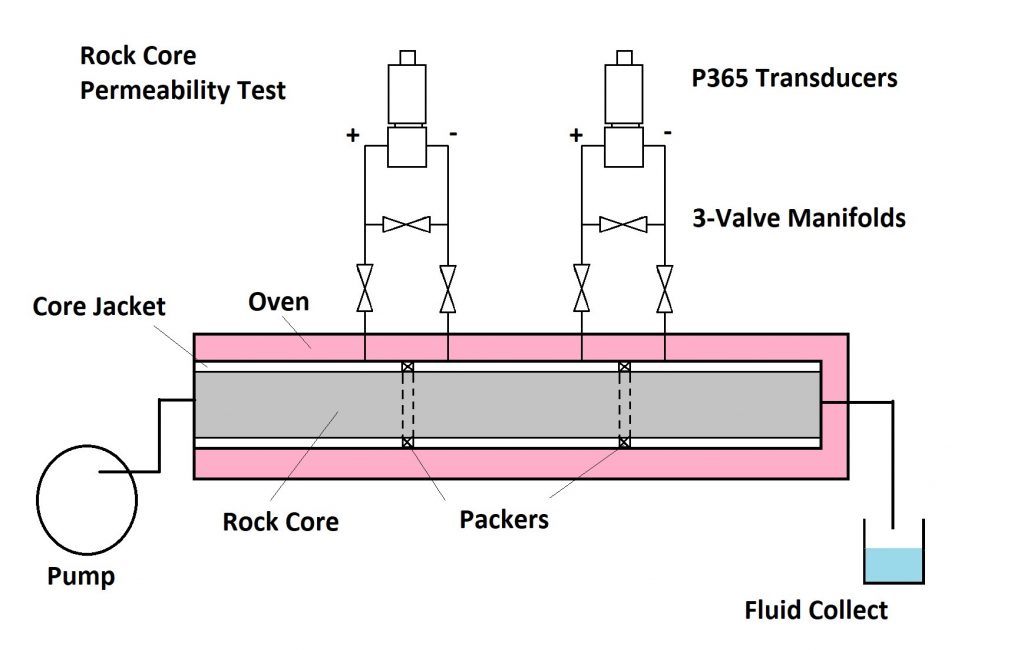

Leak Testing with Pressure Transducers: Updated for Today’s Demands

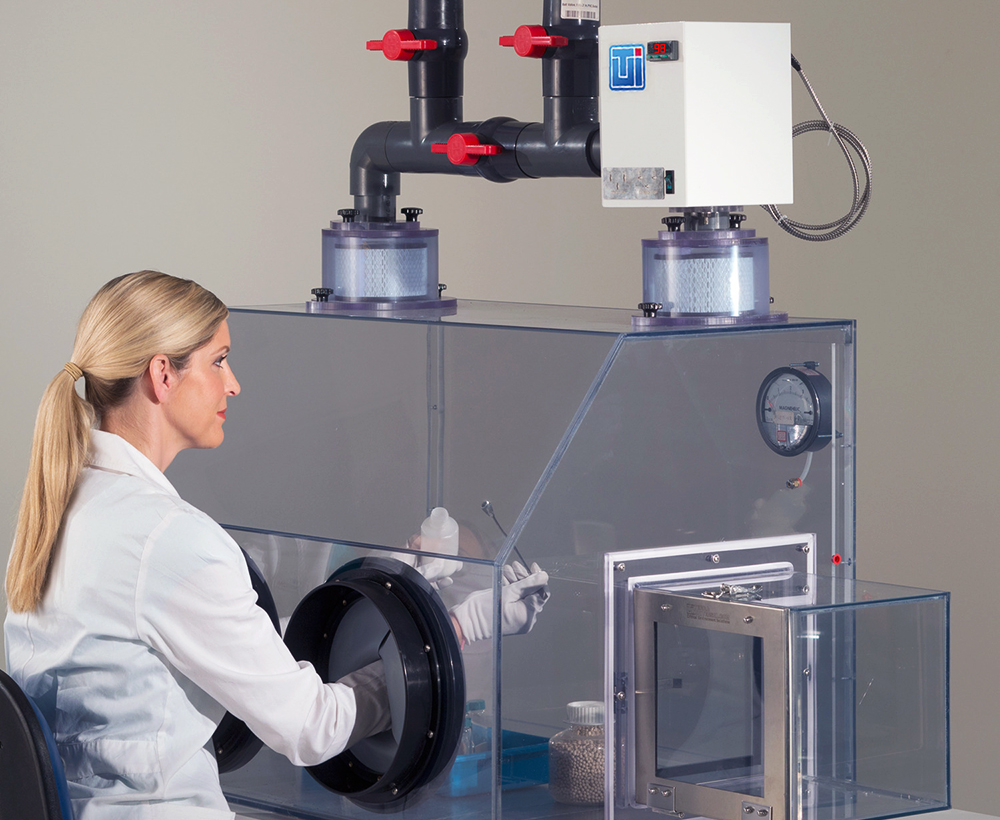

Ensuring Product Integrity, One Leak Test at a Time Leak testing remains a critical quality control step across industries—from automotive to aerospace to medical devices. The traditional method of pressurizing…

Read More