Oil & Gas, Utility

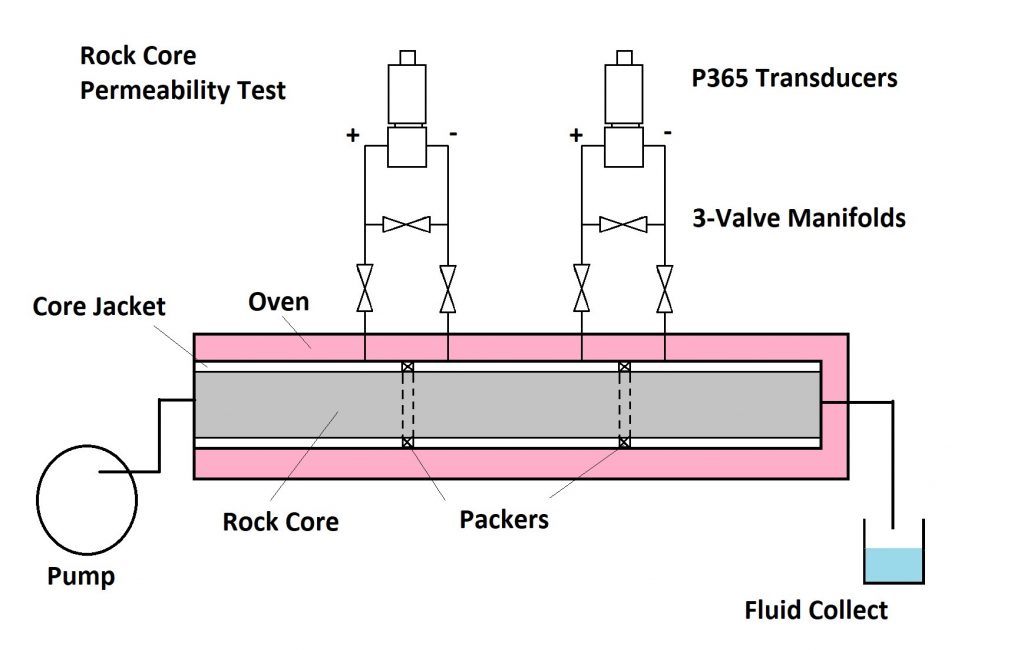

Petroleum Core Testing

How much oil will come out of an oil field? Is it worth developing once it is discovered? These are not trivial questions if you must drill and complete your…

Read More