Pressure Measurement, Utility

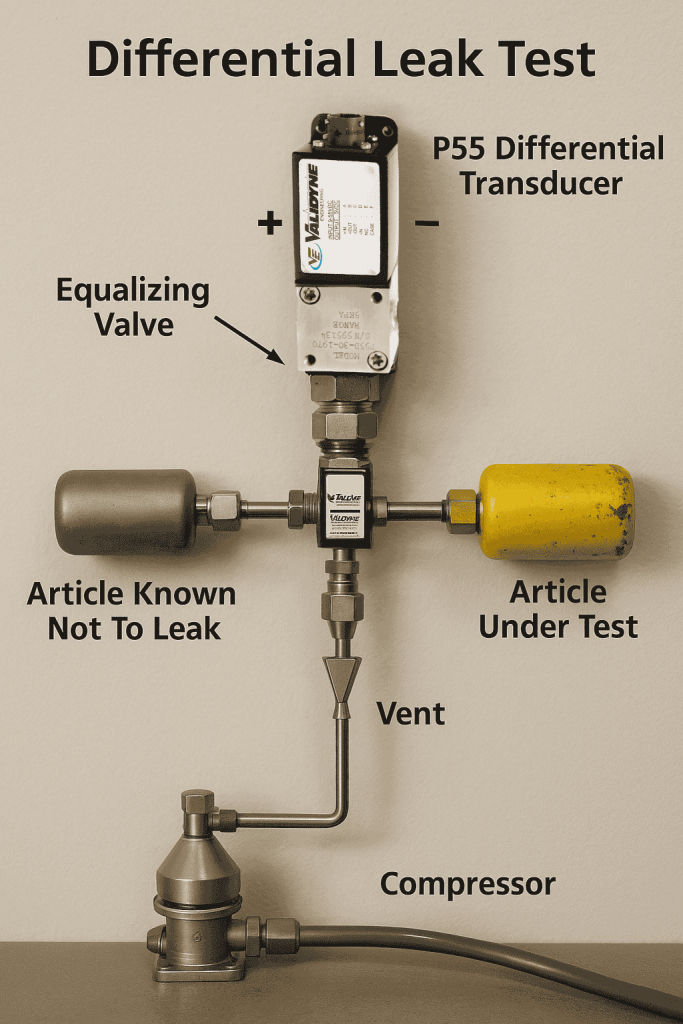

Leak Testing with Pressure Transducers: Updated for Today’s Demands

Ensuring Product Integrity, One Leak Test at a Time Leak testing remains a critical quality control step across industries—from automotive to aerospace to medical devices. The traditional method of pressurizing…

Read More